- Certified Engineering Technologist, Completed , January 2010

What's your job?

Industrial Engineer Resume Samples and Templates for 2026

- Table of Contents

- Downloadable Sample

- Resume Tips from Experts

- Resume Text Version

- Share

Industrial Engineer Resume Examples and Templates: A Complete Guide

A professional industrial engineer resume is essential for standing out in India’s rapidly growing manufacturing and process improvement sector. Whether you’re applying for positions at automotive giants like Tata Motors and Maruti Suzuki, manufacturing leaders like L&T or Godrej, or seeking opportunities in consulting firms specialising in operational excellence, your resume should highlight your process optimisation skills, technical expertise, and measurable productivity improvements.

This guide walks you through industrial engineer resume examples and templates, formatting tips, and keywords to help you write a resume that stands out to recruiters at leading manufacturing and consulting companies in India.

Understanding the Industrial Engineer Role in India

Industrial engineers in India are critical drivers of efficiency across manufacturing, logistics, healthcare, and service industries. From optimising production lines at automobile plants to improving warehouse operations in e-commerce fulfilment centres, industrial engineers apply scientific methods to enhance productivity and reduce waste.

Key responsibilities include:

- Analysing and improving manufacturing and service processes

- Implementing Lean Manufacturing and Six Sigma methodologies

- Conducting time and motion studies for productivity improvement

- Designing facility layouts and material flow systems

- Developing standard operating procedures (SOPs)

- Leading kaizen and continuous improvement initiatives

- Analysing production data for capacity planning

- Reducing costs while maintaining quality standards

India’s emphasis on manufacturing growth under “Make in India” and increasing focus on operational excellence create strong demand for skilled industrial engineers across all sectors.

Preparing to Write Your Industrial Engineer Resume

Before drafting your resume, gather all relevant information:

Professional details to compile:

- Complete employment history in industrial engineering roles

- Process improvement projects completed

- Cost savings and productivity gains achieved

- Lean Six Sigma certifications held

- Software and tools proficiency

- Team size led and cross-functional experience

- Manufacturing processes worked with

- Notable achievements and recognition

Research target employers:

- Review requirements from manufacturing companies like Tata, Mahindra, L&T

- Understand expectations at consulting firms like McKinsey, BCG, Deloitte

- Note specific methodologies mentioned in job descriptions

Choosing the Best Resume Format

Select a format that best presents your industrial engineering experience:

Chronological Format

Best for industrial engineers with steady career progression in manufacturing or consulting. Highlights your work at companies in reverse chronological order, ideal for those with 3+ years of experience.

Functional Format

Suitable for fresh graduates, career changers, or those entering industrial engineering from related fields who want to emphasise skills and project work over employment history.

Combination Format

Ideal for mid-career professionals balancing diverse experience across manufacturing sectors, consulting, and operational roles.

Format recommendations by experience: | Experience Level | Recommended Format | Resume Length | |-----------------|-------------------|---------------| | Entry-level (0-2 years) | Chronological | 1 page | | Mid-level (3-8 years) | Combination | 1-2 pages | | Senior (8+ years) | Chronological | 2 pages |

Professional Summary Examples

Your professional summary should immediately communicate your industrial engineering expertise:

Entry-Level Industrial Engineer

B.Tech Industrial Engineering graduate from NIT Trichy seeking industrial engineering position in manufacturing sector. Completed internship at Tata Motors Pune implementing 5S and visual management on assembly line. Proficient in AutoCAD, Minitab, and MS Excel. Trained in Lean Manufacturing principles and time study techniques. Eager to apply problem-solving skills to drive operational excellence and productivity improvements.

Experienced Industrial Engineer

Results-driven industrial engineer with 6+ years of experience in process optimisation and productivity improvement in automotive manufacturing. Currently Senior Industrial Engineer at Maruti Suzuki Gurugram leading kaizen initiatives across 3 production lines. Expertise in Lean Six Sigma, work measurement, and capacity planning. Delivered ₹15 crore annual savings through process improvements. Lean Six Sigma Black Belt with strong analytical and project management skills.

Senior Industrial Engineer

Strategic industrial engineering leader with 12+ years of experience driving operational excellence across manufacturing and logistics. Currently Manager - Industrial Engineering at Mahindra & Mahindra Nashik heading team of 8 engineers. Led digital manufacturing transformation implementing IoT-based OEE tracking. Delivered ₹50 crore cumulative savings over 5 years. B.Tech from IIT Kharagpur with MBA in Operations from IIM Ahmedabad.

Industrial Engineering Consultant

Industrial engineering consultant with 10 years of experience advising manufacturing clients on operational transformation. Currently Associate Principal at McKinsey India leading manufacturing practice engagements. Expertise in Lean transformation, supply chain optimisation, and Industry 4.0 implementation. Delivered $100M+ impact across 25+ client engagements. Certified Master Black Belt with extensive change management experience.

Showcasing Your Work Experience

Present your industrial engineering experience with specific achievements and metrics:

Manager - Industrial Engineering

Mahindra & Mahindra | Nashik April 2018 – Present

- Lead team of 8 industrial engineers supporting 4 vehicle assembly lines

- Implement Lean Manufacturing initiatives delivering ₹12 crore annual savings

- Reduced cycle time by 25% through line balancing and method improvement

- Led digitisation of time study and work measurement processes

- Implemented IoT-based OEE tracking achieving 85%+ equipment effectiveness

- Coordinate with cross-functional teams on new model launch efficiency

- Conduct manpower planning and capacity studies for volume changes

- Chair plant-level kaizen committee evaluating 500+ suggestions annually

Senior Industrial Engineer

Tata Motors | Pune June 2014 – March 2018

- Led process improvement projects across welding and paint shops

- Conducted time studies and line balancing for 3 new model launches

- Implemented standardised work procedures reducing defects by 35%

- Achieved ₹8 crore savings through material flow optimisation

- Trained 50+ operators on standard work and continuous improvement

- Developed capacity planning models for volume forecasting

- Led Lean transformation initiatives across 2 production lines

- Received “Excellence in IE” award for productivity improvements

Industrial Engineer

Hero MotoCorp | Haridwar July 2011 – May 2014

- Conducted time and motion studies for motorcycle assembly operations

- Developed standard operating procedures for 200+ workstations

- Analysed production data identifying bottleneck operations

- Supported new product industrialisation with process planning

- Implemented 5S and visual management across facility

- Participated in supplier quality and process improvement initiatives

Essential Skills for Industrial Engineers

Technical Skills

- Lean Manufacturing and Six Sigma

- Time and motion study

- Work measurement and methods analysis

- Capacity planning and line balancing

- Facility layout and material flow

- Value stream mapping

- Statistical process control (SPC)

- Design of experiments (DOE)

- AutoCAD and layout software

- Minitab and statistical analysis tools

Methodology Expertise

- Kaizen and continuous improvement

- 5S and visual management

- Total Productive Maintenance (TPM)

- Quick changeover (SMED)

- Error-proofing (Poka-Yoke)

- Root cause analysis

- DMAIC problem-solving

- Theory of Constraints (TOC)

- Hoshin planning

- A3 thinking

Soft Skills

- Analytical thinking

- Problem-solving

- Data-driven decision making

- Project management

- Cross-functional collaboration

- Change management

- Presentation and reporting

- Stakeholder management

- Team leadership

- Training and coaching

Certifications for Industrial Engineers

Professional Certifications

| Certification | Issuing Body | Relevance |

|---|---|---|

| Lean Six Sigma Black Belt | ASQ/IASSC | Advanced process improvement |

| Lean Six Sigma Green Belt | ASQ/IASSC | Process improvement foundation |

| Certified Quality Engineer | ASQ | Quality management |

| PMP Certification | PMI | Project management |

| Lean Bronze/Silver/Gold | SME/AME | Lean expertise |

| Industry 4.0 Certification | Various | Digital manufacturing |

Academic Qualifications

- B.Tech/B.E. in Industrial Engineering (NIT, IITs)

- B.Tech/B.E. in Mechanical/Production Engineering

- M.Tech in Industrial Engineering and Management

- MBA in Operations Management

- PGDM in Operations (IIMs, NITIE)

Indian-Specific Training

- CII Lean Manufacturing programmes

- AIMA Operations Management certification

- NITIE short-term programmes

- TQM certification courses

- Kaizen Institute training

- Toyota Production System training

Tips by Experience Level

Entry-Level Industrial Engineers (0-2 years)

- Highlight B.Tech from recognised institutions (NITs, IITs)

- Include internship projects with quantifiable outcomes

- Emphasise software proficiency (AutoCAD, Minitab, Excel)

- Showcase Lean Six Sigma training and certifications

- Include academic projects on process improvement

Target employers: Automobile OEMs, manufacturing companies, management trainee roles

Mid-Level Industrial Engineers (3-8 years)

- Quantify savings delivered and productivity improvements

- Highlight specific methodologies implemented (Lean, Six Sigma)

- Showcase project leadership and team coordination

- Demonstrate cross-functional collaboration experience

- Include certifications (Green Belt, Black Belt)

Target positions: Senior IE, Lead IE, Manager - Industrial Engineering

Senior Industrial Engineers (8+ years)

- Emphasise leadership and team management experience

- Highlight strategic initiatives and transformation projects

- Showcase cumulative business impact and savings

- Demonstrate digital manufacturing and Industry 4.0 experience

- Include industry recognition and thought leadership

Target positions: Head of IE, Plant Manager, VP Operations, Consulting Principal

ATS Optimisation for Industrial Engineer Resumes

Ensure your resume passes Applicant Tracking Systems:

Essential keywords to include:

- Industrial engineer, industrial engineering

- Lean Manufacturing, Six Sigma, kaizen

- Process improvement, productivity

- Time study, work measurement

- Capacity planning, line balancing

- Cost reduction, efficiency

- Manufacturing, operations

- Green Belt, Black Belt

- AutoCAD, Minitab

- OEE, SPC, DMAIC

ATS-friendly formatting:

- Use standard section headings (Summary, Experience, Skills, Education)

- List certifications with issuing body names

- Avoid tables, graphics, and complex formatting

- Use standard fonts (Arial, Calibri, Times New Roman)

- Include savings figures and percentages as numbers

Conclusion

A professional industrial engineer resume is essential for success in India’s growing manufacturing sector. Whether you’re targeting positions at automotive OEMs like Tata Motors and Maruti Suzuki, or exploring opportunities at consulting firms and manufacturing companies, your resume must demonstrate your process improvement expertise, technical capabilities, and measurable business impact.

Focus on quantifying your achievements—savings delivered, productivity improvements, and efficiency gains. Highlight your Lean Six Sigma certifications and methodology expertise that validate your skills. With India’s emphasis on manufacturing excellence and operational efficiency, skilled industrial engineers have excellent career opportunities across industries.

Use our resume builder to create an ATS-optimised industrial engineer resume, or explore our professional templates designed specifically for engineering professionals in India.

Frequently Asked Questions

What sections should a strong industrial engineer resume include?

At minimum, include contact information, a professional summary, work experience, key skills, and education. Depending on your experience level, you may also add certifications, achievements, projects, or industry-specific sections that highlight your expertise.

How do I write a professional summary for an industrial engineer role?

Keep it concise — two to three sentences highlighting your experience level, core competencies, and a key achievement or strength that shows why you're right for the job. Tailor it to match the specific role you're applying for.

What skills are most important to list on an industrial engineer resume?

Include a mix of technical skills specific to industrial engineer roles and soft skills like communication, problem-solving, and teamwork. Research job postings in your target companies to identify the most commonly requested skills.

How detailed should my work experience be?

Use bullet points to describe your roles, focusing on specific results, tools used, and the impact you made. Quantify achievements where possible — numbers and percentages help recruiters quickly understand your contributions.

Do I need certifications on my industrial engineer resume?

Certifications aren't always required, but they can strengthen your application — especially if they demonstrate advanced training or specialised expertise. List the certification name, issuing organisation, and year obtained.

What's the best resume format for an industrial engineer?

Most industrial engineer professionals benefit from a reverse-chronological format that lists your most recent experience first. If you're changing careers or have gaps, a functional or combination format might work better.

How long should my industrial engineer resume be?

Aim for one page if you're early in your career. Experienced professionals with extensive achievements can use two pages — just ensure every section adds value and remains relevant to the role.

Should I tailor my resume for each job application?

Yes. Customising your resume with keywords and responsibilities from the job posting improves your chances of passing Applicant Tracking Systems (ATS) and resonating with recruiters. Focus on relevant experience and skills for each role.

Industrial Engineer Text-Only Resume Templates and Samples

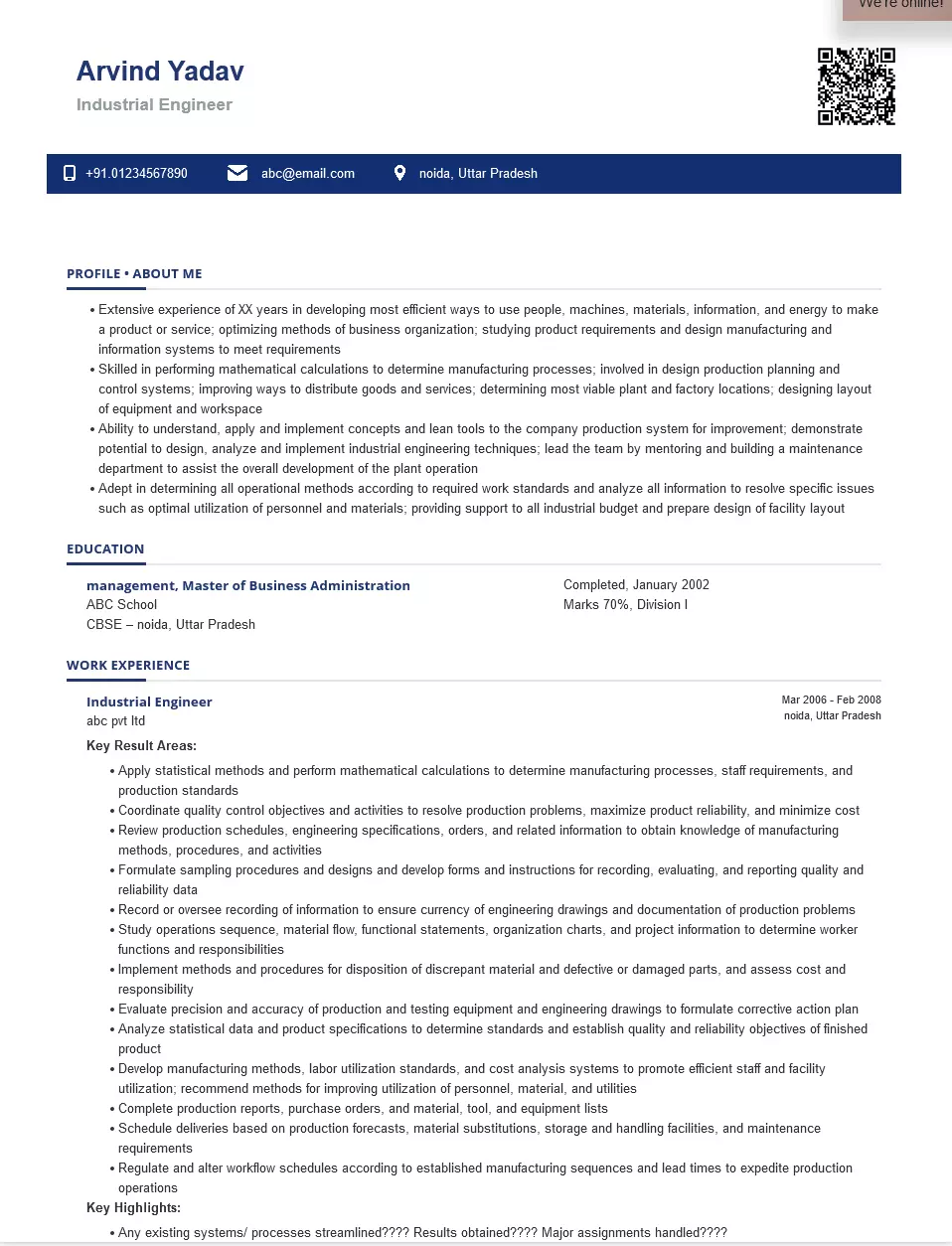

Arvind Yadav

Phone: 01234567890

Email: abc@email.com

Address: Sec-44, Noida, Noida

About Me

Industrial Engineer

- An industrial engineer with more than XX years of experience and specialization in performing quality troubleshooting and implementing new system designs. Skilled in performing mathematical calculations to determine manufacturing processes. Ability to understand, apply and implement concepts and lean tools to the company production system for improvement. Skilled in performing mathematical calculations to determine manufacturing processes; involved in designing production planning and control systems; improving ways to distribute goods and services; determining most viable plant and factory locations; designing the layout of equipment and workspace

- Ability to understand, apply and implement concepts and lean tools to the company production system for improvement; demonstrate the potential to design, analyze and implement industrial engineering techniques; lead the team by mentoring and building a maintenance department to assist the overall development of the plant operation

- Adept in determining all operational methods according to required work standards and analyzing all information to resolve specific issues such as optimal utilization of personnel and materials; providing support to all industrial budgets and preparing the design of facility layout

Education

Industrial Engineering , Bachelor of Engineering / Bachelor of Technology, Completed, January 2002

DTR College of Engineering

Delhi University

Delhi,

Certifications

Work Experience

Period: March 2011 - Current

Senior Industrial Engineer

Siemens Technology

- Applied statistical methods and performed mathematical calculations to determine manufacturing processes, staff requirements, and production standards.

- Coordinated quality control objectives and activities to resolve production problems, maximize product reliability, and minimize cost.

- Reviewed production schedules, engineering specifications, orders, and related information to obtain knowledge of manufacturing methods, procedures, and activities.

- Recorded or oversee the recording of information to ensure currency of engineering drawings and documentation of production problems.

- Studied operations sequence, material flow, functional statements, organization charts, and project information to determine worker functions and responsibilities

- Formulated sampling procedures and designs and develop forms and instructions for recording, evaluating, and reporting quality and reliable data.

- Implemented methods and procedures for the disposition of discrepant material and defective or damaged parts, and assess cost and responsibility

Period: July 1999 - February 2010

Industrial Engineer

AEV Ltd.

- Reviewed production schedules, engineering specifications, process flows, and other information to understand methods and activities in manufacturing and services.

- Figured out how to manufacture parts or products, or deliver services, with maximum efficiency.

- Developed management control systems to make financial planning and cost analysis more efficient.

- Enacted quality control procedures to resolve production problems or minimize costs.

- Designed control systems to coordinate activities and production planning to ensure that products meet quality standards.

- Worked with customers and management to develop standards for design and production.

- Conferred with clients about product specifications, vendors about purchases, management personnel about manufacturing capabilities, and staff about the status of projects.

Skills

Hard Skills

- Production and Processing

- Statistical Analysis and Modeling

- Inventory Control

- Data Analysis and Visualization

- Process Analysis

- Factory Planning

- Material Handling

Soft Skills

- Interpersonal Skills

- Ability to Work Under Pressure

- Analytical Skills

- Communication Skills

- Good Team Player

- Time Management

Languages

Softwares

Operating System

Personal Interests

- Basketball

- Video Games

- Gardening

India's

premier resume service

India's

premier resume service