- Certified Industrial Machine Mechanic, Completed , January 2008

What's your job?

Industrial Machinery Resume Samples and Templates for 2026

- Table of Contents

- Downloadable Sample

- Resume Tips from Experts

- Resume Text Version

- Share

Industrial Machinery Resume Examples and Templates: A Complete Guide

A professional industrial machinery resume is essential for standing out in India’s growing manufacturing and heavy engineering sector. Whether you’re applying for positions at machinery manufacturers like Larsen & Toubro, BHEL, or Kirloskar, or seeking opportunities at automotive plants and process industries, your resume should highlight your technical expertise, equipment knowledge, and hands-on experience with industrial machinery.

This guide walks you through industrial machinery resume examples and templates, formatting tips, and keywords to help you write a resume that stands out to recruiters at leading manufacturing companies in India.

Understanding the Industrial Machinery Role in India

Industrial machinery professionals are essential to India’s manufacturing backbone, ensuring that production equipment runs efficiently and products meet quality standards. From operating CNC machines at precision engineering companies to maintaining heavy machinery at steel plants, these professionals keep Indian industry running.

Key responsibilities include:

- Operating various industrial machinery and equipment

- Performing preventive and breakdown maintenance

- Reading and interpreting engineering drawings and specifications

- Setting up machines for production runs

- Monitoring equipment performance and quality output

- Troubleshooting mechanical and electrical faults

- Maintaining safety standards and compliance

- Training junior operators on equipment operation

India’s manufacturing growth under “Make in India” and increasing industrial automation create strong demand for skilled machinery professionals across sectors.

Preparing to Write Your Industrial Machinery Resume

Before drafting your resume, gather all relevant information:

Professional details to compile:

- Complete employment history in machinery roles

- Types of equipment operated and maintained

- Production volumes and efficiency metrics

- Safety certifications and training completed

- Technical qualifications and trade certificates

- Software and CNC programming knowledge

- Notable achievements and recognition

- Languages known

Research target employers:

- Review requirements from heavy engineering companies like L&T, BHEL

- Understand expectations at automotive OEMs like Tata Motors, Maruti

- Note specific machinery and skills mentioned in job descriptions

Choosing the Best Resume Format

Select a format that best presents your machinery experience:

Chronological Format

Best for machinery professionals with steady career progression. Highlights your work at companies in reverse chronological order, ideal for those with 3+ years of experience.

Functional Format

Suitable for ITI freshers, career changers, or those entering the industry from related trades who want to emphasise skills over employment history.

Combination Format

Ideal for mid-career professionals balancing diverse experience across different types of machinery and industries.

Format recommendations by experience: | Experience Level | Recommended Format | Resume Length | |-----------------|-------------------|---------------| | Entry-level (0-2 years) | Chronological | 1 page | | Mid-level (3-8 years) | Combination | 1-2 pages | | Senior (8+ years) | Chronological | 2 pages |

Professional Summary Examples

Your professional summary should immediately communicate your machinery expertise:

Entry-Level Machine Operator

ITI-certified fitter seeking machine operator position in manufacturing sector. Completed apprenticeship at BHEL Trichy learning operation of lathe, milling, and drilling machines. Proficient in reading engineering drawings and using measuring instruments. Trained in safety protocols and 5S practices. Eager to apply hands-on skills while developing expertise in CNC machining and industrial automation.

Experienced Machinist

Skilled machinist with 7+ years of experience operating and maintaining CNC and conventional machines in precision engineering. Currently Senior Machinist at Godrej Precision Engineering Mumbai achieving 98% first-pass yield on complex components. Expertise in CNC turning, milling, and grinding with proficiency in Fanuc and Siemens controls. Trained 20+ operators on machine setup and programming. ITI fitter with Diploma in Mechanical Engineering.

Senior Machinery Technician

Experienced machinery technician with 12+ years in heavy industrial equipment maintenance and operation. Currently Maintenance Supervisor at Tata Steel Jamshedpur leading team of 15 technicians maintaining rolling mill equipment. Expertise in hydraulics, pneumatics, and industrial automation. Achieved 95%+ equipment availability through preventive maintenance programme. Diploma holder with Six Sigma Green Belt certification.

CNC Programmer and Operator

CNC specialist with 10 years of experience in programming and operating advanced machining centres. Currently Lead CNC Programmer at Mahindra Engineering Services Pune handling 5-axis machining for aerospace components. Expertise in Mastercam, Siemens NX, and Fanuc programming. Reduced cycle time by 30% through optimised toolpaths. Certified in GD&T and precision measurement techniques.

Showcasing Your Work Experience

Present your machinery experience with specific achievements and metrics:

Maintenance Supervisor

Tata Steel | Jamshedpur April 2018 – Present

- Supervise 15-member maintenance team for hot rolling mill equipment

- Implement preventive maintenance programme achieving 95% equipment uptime

- Coordinate breakdown repairs reducing mean time to repair by 40%

- Manage spare parts inventory worth ₹5 crore ensuring availability

- Lead major shutdown maintenance planning and execution

- Conduct root cause analysis for recurring equipment failures

- Train technicians on new equipment and safety procedures

- Chair daily production meetings coordinating with operations

Senior Machinist

Godrej Precision Engineering | Mumbai June 2014 – March 2018

- Operated CNC turning and milling centres for precision components

- Achieved 98% first-pass yield on aerospace and defence parts

- Set up machines for complex jobs meeting tight tolerances (±0.01mm)

- Programmed CNC machines using Fanuc and Siemens controls

- Trained 15 junior operators on machine operation and setup

- Implemented tool life management reducing tooling costs by 25%

- Participated in quality improvement initiatives

- Received “Best Machinist” award for productivity (2017)

Machine Operator

Larsen & Toubro | Vadodara July 2011 – May 2014

- Operated lathe, milling, and drilling machines for valve components

- Read engineering drawings and ensured dimensional accuracy

- Performed first-piece inspections using measuring instruments

- Maintained daily production logs and quality records

- Followed safety protocols and housekeeping standards

- Participated in kaizen activities for process improvement

- Completed company apprenticeship programme successfully

Essential Skills for Industrial Machinery Professionals

Technical Skills

- CNC machine operation (turning, milling, grinding)

- Conventional machine operation

- Machine setup and tool changeover

- CNC programming (Fanuc, Siemens, Mazak)

- CAM software (Mastercam, Siemens NX)

- Reading engineering drawings and GD&T

- Precision measurement (CMM, micrometers, gauges)

- Hydraulics and pneumatics

- PLC basics and industrial automation

- Welding and fabrication

Maintenance Skills

- Preventive and breakdown maintenance

- Troubleshooting mechanical systems

- Electrical fault diagnosis

- Lubrication and condition monitoring

- Spare parts management

- Root cause analysis

- Shutdown planning and execution

- Equipment installation and commissioning

- Calibration procedures

- Safety systems maintenance

Soft Skills

- Attention to detail

- Safety consciousness

- Problem-solving

- Teamwork and coordination

- Time management

- Quality focus

- Communication skills

- Adaptability to shifts

- Physical stamina

- Continuous learning attitude

Certifications for Industrial Machinery Professionals

Professional Certifications

| Certification | Issuing Body | Relevance |

|---|---|---|

| ITI Fitter/Turner/Machinist | NCVT/SCVT | Trade qualification |

| Diploma in Mechanical Engineering | State Polytechnics | Technical foundation |

| CNC Programming Certificate | NTTF/IGTR | CNC expertise |

| Welding Certification | ASNT/AWS | Welding proficiency |

| Maintenance Technician | Various | Maintenance skills |

| Industrial Safety | NSDC/Various | Safety compliance |

Academic Qualifications

- B.E./B.Tech in Mechanical Engineering

- Diploma in Mechanical/Production Engineering

- ITI in Fitter, Turner, Machinist, or related trades

- Certificate in CNC Technology

- Diploma in Tool and Die Making

Safety Certifications

- Industrial Safety Certificate

- First Aid and CPR training

- Fire safety certification

- Height work certification

- Confined space entry

- Electrical safety for mechanical workers

Tips by Experience Level

Entry-Level Machine Operators (0-2 years)

- Highlight ITI/Diploma with trade specialisation

- Include apprenticeship and OJT experience

- Emphasise tools and equipment proficiency

- Mention safety training and 5S knowledge

- Include any OEM training certificates

Target employers: Large manufacturing companies, PSUs, automotive OEMs

Mid-Level Machinists (3-8 years)

- Quantify production volumes and quality metrics

- Highlight specific machine expertise (CNC makes)

- Showcase productivity improvements achieved

- Demonstrate programming and setup capabilities

- Include training and mentoring experience

Target positions: Senior Machinist, Lead Operator, Setup Technician

Senior Machinery Professionals (8+ years)

- Emphasise team leadership and supervision

- Highlight maintenance programme implementation

- Showcase equipment availability improvements

- Demonstrate cost savings and efficiency gains

- Include cross-functional coordination experience

Target positions: Supervisor, Maintenance In-charge, Shop Floor Manager

ATS Optimisation for Industrial Machinery Resumes

Ensure your resume passes Applicant Tracking Systems:

Essential keywords to include:

- Machinist, machine operator, CNC operator

- Industrial machinery, manufacturing

- CNC turning, milling, grinding

- Fanuc, Siemens, Mazak

- Maintenance, preventive maintenance

- ITI, fitter, turner, machinist

- Production, quality, safety

- Engineering drawings, GD&T

- Hydraulics, pneumatics

- Troubleshooting, setup

ATS-friendly formatting:

- Use standard section headings (Summary, Experience, Skills, Education)

- List certifications with issuing body names

- Avoid tables, graphics, and complex formatting

- Use standard fonts (Arial, Calibri, Times New Roman)

- Include production volumes and metrics as numbers

Conclusion

A professional industrial machinery resume is essential for success in India’s growing manufacturing sector. Whether you’re targeting positions at heavy engineering companies like L&T and BHEL, or exploring opportunities at precision engineering firms and automotive OEMs, your resume must demonstrate your technical expertise, equipment proficiency, and commitment to quality and safety.

Focus on quantifying your achievements—production volumes, quality metrics, and efficiency improvements. Highlight your trade certifications and machine-specific expertise that set you apart. With India’s emphasis on manufacturing growth and industrial modernisation, skilled machinery professionals have excellent career opportunities across sectors.

Use our resume builder to create an ATS-optimised industrial machinery resume, or explore our professional templates designed specifically for manufacturing professionals in India.

Frequently Asked Questions

What sections should a strong industrial machinery resume include?

At minimum, include contact information, a professional summary, work experience, key skills, and education. Depending on your experience level, you may also add certifications, achievements, projects, or industry-specific sections that highlight your expertise.

How do I write a professional summary for an industrial machinery role?

Keep it concise — two to three sentences highlighting your experience level, core competencies, and a key achievement or strength that shows why you're right for the job. Tailor it to match the specific role you're applying for.

What skills are most important to list on an industrial machinery resume?

Include a mix of technical skills specific to industrial machinery roles and soft skills like communication, problem-solving, and teamwork. Research job postings in your target companies to identify the most commonly requested skills.

How detailed should my work experience be?

Use bullet points to describe your roles, focusing on specific results, tools used, and the impact you made. Quantify achievements where possible — numbers and percentages help recruiters quickly understand your contributions.

Do I need certifications on my industrial machinery resume?

Certifications aren't always required, but they can strengthen your application — especially if they demonstrate advanced training or specialised expertise. List the certification name, issuing organisation, and year obtained.

What's the best resume format for an industrial machinery?

Most industrial machinery professionals benefit from a reverse-chronological format that lists your most recent experience first. If you're changing careers or have gaps, a functional or combination format might work better.

How long should my industrial machinery resume be?

Aim for one page if you're early in your career. Experienced professionals with extensive achievements can use two pages — just ensure every section adds value and remains relevant to the role.

Should I tailor my resume for each job application?

Yes. Customising your resume with keywords and responsibilities from the job posting improves your chances of passing Applicant Tracking Systems (ATS) and resonating with recruiters. Focus on relevant experience and skills for each role.

Industrial Machinery Text-Only Resume Templates and Samples

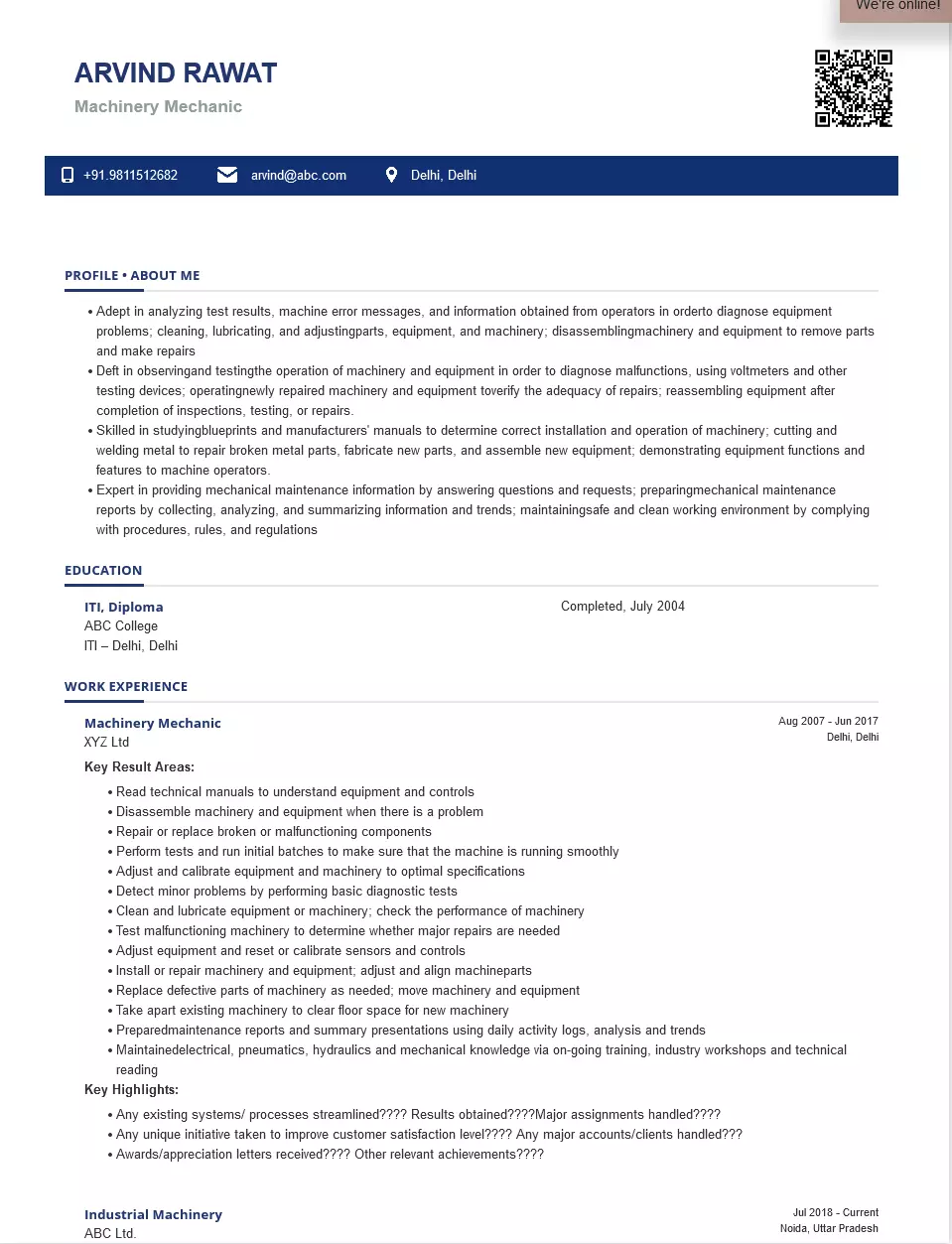

ARVIND RAWAT

Phone: 9811512682

Email: arvind@abc.com

Address: C-21, Sector-21, Delhi

About Me

Industrial Machinery Mechanic / Material Handling Machinery & Equipment

- Knowledgeable Industrial Machinery Mechanic with XX years of experience in analyzing test results, machine error messages, and information obtained from operators in order to diagnose equipment problems.

- Adept in cleaning, lubricating, and adjusting parts, equipment, and machinery; disassembling machinery and equipment to remove parts and make repairs

- Deft in observing and testing the operation of machinery and equipment in order to diagnose malfunctions, using voltmeters and other testing devices; operating newly repaired machinery and equipment to verify the adequacy of repairs; reassembling equipment after completion of inspections, testing, or repairs.

- Skilled in studying blueprints and manufacturers' manuals to determine correct installation and operation of machinery; cutting and welding metal to repair broken metal parts, fabricating new parts, and assembling new equipment; demonstrating equipment functions and features to machine operators.

- Expert in providing mechanical maintenance information by answering questions and requests; preparing mechanical maintenance reports by collecting, analyzing, and summarizing information and trends; maintaining safe and clean working environment by complying with procedures, rules, and regulations

Education

, Machine Tool Technology, Completed, July 2004

Aadhunik Private Industrial Training Institute

– Marks null

Varanasi, UP

Certifications

Work Experience

Period: August 2018 - Current

Industrial Automation Engineer / Consultant, Machinery and Equipment

Kroll | Risk and Financial Advisory Solutions

- Read technical manuals to understand equipment and controls.

- Disassemble machinery and equipment when there is a problem.

- Repair or replace broken or malfunctioning components.

- Perform tests and run initial batches to make sure that the machine is running smoothly.

- Adjust equipment and reset or calibrate sensors and controls.

- Install or repair machinery and equipment; adjust and align machine parts.

- Replace defective parts of machinery as needed; move machinery and equipment.

- Take apart existing machinery to clear floor space for new machinery.

- Prepared maintenance reports and summary presentations using daily activity logs, analysis, and trends.

- Maintained electrical, pneumatics, hydraulics, and mechanical knowledge via ongoing training, industry workshops, and technical reading.

Period: July 2013 - February 2017

Service Engineer - Industrial Equipment

Dhruv Corporate HR Solutions Pvt. Ltd

- Ensured correct and safe operation of equipment and machinery using a computerized maintenance management system.

- Identified faulty equipment through observation and testing metrics.

- Troubleshoot and maintain engines, conveyors, electrical systems, machinery, pneumatic tools, and hydraulic equipment; sourced replacement parts and perform repairs.

- Worked with the facility manager to continually update the production process and system software

- Attended daily shift meetings to prioritize work orders and minimize downtime.

- Safely operated cranes, power tools, hoists, and hand tools and maintained parts and tools inventory.

- Assessed the condition of used parts using micrometers, calipers, and specifications.

Skills

Hard Skills

- Vast mechanical knowledge

- Complete repair services

- Preventative and scheduled maintenance

- Breakdown large machines

- Safety precautions

- Respond quickly to emergencies

- Initiative to work independently

- Flexible schedule

- Troubleshooting specialist

Soft Skills

- Strategic thinker

- Communication Skills

- Compassion & Empathy

- Interpersonal Skills

- Organizational Skills

- Creativity & Innovation

- Patience & Understanding

- Enthusiasm & Friendliness

- Respectful

- Collaboration

Languages

Softwares

Operating System

Personal Interests

- Travelling

- Yoga

- Gardening

India's

premier resume service

India's

premier resume service