- CSQA (Certified Software Quality Analyst Certification), Completed , January 2015

- CAST (Certified Associate in Software Testing), Completed , January 2019

What's your job?

Testing and Inspectors Resume Samples and Templates for 2026

- Table of Contents

- Downloadable Sample

- Resume Tips from Experts

- Resume Text Version

- Share

Quality Inspector Resume Guide for India

A well-crafted quality inspector resume is essential for success in India’s massive manufacturing and quality control sector. Whether you’re pursuing a career with Tata Motors, Maruti Suzuki, L&T, Reliance Industries, Cipla, Sun Pharma, or multinational companies like Bosch, Siemens, ABB, this guide provides everything you need to create a standout resume.

This comprehensive guide includes:

- Resume format recommendations for QC/QA roles in India

- Key skills employers look for in quality inspectors

- Complete resume example with Indian context

- Top quality control employers in India

- Salary insights in INR by experience level

- Required qualifications and certifications

- ATS optimization tips for Indian job portals

Why Your Quality Inspector Resume Matters in India

India’s manufacturing sector is one of the world’s largest, with automotive, pharmaceuticals, electronics, and heavy engineering driving growth. Quality control professionals are essential for ensuring product quality, compliance with standards, and customer satisfaction.

A strong quality inspector resume helps you:

- Stand out from competition for QC/QA positions

- Showcase expertise in inspection, testing, and quality assurance

- Demonstrate knowledge of quality standards and procedures

- Highlight relevant certifications and technical skills

Manufacturing companies receive many applications. Your resume must immediately communicate your inspection expertise, quality focus, and ability to maintain standards.

Quality Inspector Resume Format for India

Indian manufacturing employers prefer professional resume formats that highlight technical skills and quality experience.

Recommended Format

- Length: 1-2 pages

- Layout: Reverse chronological

- Font: Arial, Calibri, or Times New Roman (11-12pt)

- Sections: Contact, Summary, Skills, Experience, Education, Certifications

Personal Details for Indian QC Resumes

Include:

- Full name

- Phone number with +91 country code

- Professional email address

- City, State

- LinkedIn profile (optional)

What to Avoid

- Personal details like religion or marital status

- Generic descriptions without specifics

- Outdated quality standards

- Salary expectations in resume

Key Skills for Quality Inspectors in India

Indian employers look for a combination of technical expertise and quality management abilities.

Inspection Skills

- Visual Inspection: Surface defects, finish quality

- Dimensional Inspection: Measurements, tolerances

- Material Testing: Hardness, tensile, chemical composition

- Non-Destructive Testing (NDT): UT, RT, MT, PT, ET

- Incoming Inspection: Raw material verification

Quality Tools & Techniques

- Statistical Quality Control (SQC): Control charts, SPC

- 7 QC Tools: Pareto, Ishikawa, histogram, control charts

- Root Cause Analysis: 5 Why, fishbone diagram

- FMEA: Failure Mode and Effects Analysis

- PPAP/APQP: Production Part Approval Process

Standards & Systems

- ISO 9001: Quality Management Systems

- IATF 16949: Automotive Quality

- ISO 17025: Laboratory Accreditation

- GMP/GLP: Pharmaceutical standards

- AS9100: Aerospace quality

Measurement Instruments

- Vernier caliper, micrometer, height gauge

- CMM (Coordinate Measuring Machine)

- Profile projector, surface roughness tester

- Hardness tester, tensile testing machine

- Gauges: plug, ring, snap, thread

Soft Skills

- Attention to Detail: Detecting defects and deviations

- Documentation: Inspection reports, NCRs

- Communication: Reporting quality issues

- Problem-Solving: Root cause analysis

- Team Coordination: Working with production

Quality Inspector Resume Example for India

Here’s a complete resume example tailored for Indian manufacturing employers:

Rajesh Kumar

Pune, Maharashtra | +91-98XXX-XXXXX | rajesh.qc@email.com | linkedin.com/in/rajeshkumar-qc

Professional Summary

Experienced Quality Inspector with 8+ years in automotive and manufacturing industries. Currently Quality Engineer at Tata Motors Pune with expertise in incoming, in-process, and final inspection for automotive components. Certified in ISO 9001:2015 and IATF 16949 with strong background in dimensional inspection, SPC, and supplier quality. Proven track record of reducing rejection rate by 35% through improved inspection processes and root cause analysis.

Key Skills

Quality Inspection | Dimensional Measurement | ISO 9001 | IATF 16949 | SPC | 7 QC Tools | PPAP | FMEA | Root Cause Analysis | CMM Operation | NDT (UT, PT) | Incoming Inspection | Supplier Quality | Documentation | GD&T | SAP QM

Certifications

- ISO 9001:2015 Lead Auditor | TUV SUD | 2023

- IATF 16949:2016 Internal Auditor | BSI | 2022

- Six Sigma Green Belt | ASQ | 2021

- NDT Level II (UT, PT) | ISNT | 2019

- Core Tools (APQP, PPAP, FMEA, SPC, MSA) | AIAG | 2020

Professional Experience

Senior Quality Engineer | Tata Motors | Pune | April 2020 – Present

- Lead quality inspection for engine components with daily production of 500+ units

- Manage incoming, in-process, and final inspection for machined components

- Operate CMM (Zeiss) for dimensional verification of critical components

- Analyse SPC data identifying trends and implementing corrective actions

- Conduct PPAP documentation for new product launches

- Perform supplier audits and manage supplier quality issues

- Reduce rejection rate from 2.5% to 1.6% through process improvements

- Train operators on quality standards and inspection methods

- Prepare monthly quality reports for management review

- Handle customer complaints and conduct 8D analysis

Key Achievements:

- 35% reduction in internal rejection rate

- Zero customer complaints for 18 consecutive months

- 5 successful PPAP submissions for new components

Quality Inspector | Mahindra & Mahindra | Nashik | June 2017 – March 2020

- Performed incoming inspection of castings and forgings

- Conducted dimensional inspection using conventional instruments

- Maintained inspection records and traceability documentation

- Participated in supplier development activities

- Handled non-conformance reports and disposition

- Supported internal and external quality audits

Key Achievements:

- Improved incoming inspection efficiency by 20%

- Certified as IATF 16949 internal auditor

Junior Quality Inspector | Bajaj Auto | Aurangabad | July 2015 – May 2017

- Performed in-process inspection for two-wheeler components

- Operated measurement instruments (vernier, micrometer, gauges)

- Documented inspection results and maintained records

- Assisted in root cause analysis for quality issues

- Learned quality tools and automotive quality systems

Education

B.E. (Mechanical Engineering) | Pune University | 2015

- First Class with Distinction (72%)

Diploma in Mechanical Engineering | MSBTE | 2012

- First Class (76%)

Projects

Rejection Reduction Project | Tata Motors | 2022

- Cross-functional project to reduce machining rejections

- Applied DMAIC methodology and root cause analysis

- Result: 35% reduction in rejection rate, ₹45 lakh annual savings

PPAP Implementation | Mahindra | 2019

- Complete PPAP documentation for new transmission component

- Coordinated with design, production, and customer quality

- Result: First-time approval from customer

Languages

Hindi (Native) | English (Fluent) | Marathi (Native)

Top Quality Inspector Employers in India

India’s manufacturing sector offers diverse opportunities for quality professionals.

Automotive Industry

- Maruti Suzuki: India’s largest carmaker

- Tata Motors: Commercial and passenger vehicles

- Mahindra & Mahindra: SUVs and tractors

- Bajaj Auto: Two-wheelers

- TVS Motor: Two-wheelers

- Hyundai India: Korean carmaker

- Honda Cars India: Japanese quality focus

Auto Components

- Bosch India: Automotive components

- Bharat Forge: Forging, machining

- Motherson Sumi: Auto parts

- Sundaram Fasteners: Fasteners, precision parts

- Valeo India: Automotive supplier

- ZF India: Transmission, chassis

Heavy Engineering

- L&T: Engineering and construction

- BHEL: Power equipment

- Thermax: Energy equipment

- Siemens India: Industrial automation

- ABB India: Electrical equipment

- Kirloskar: Pumps, engines

Pharmaceuticals

- Sun Pharma: Pharma manufacturing

- Cipla: Pharmaceutical company

- Dr. Reddy’s: Drug manufacturing

- Lupin: Pharma QC

- Biocon: Biopharmaceuticals

- Serum Institute: Vaccine manufacturing

Electronics & Consumer

- Samsung India: Electronics manufacturing

- LG Electronics: Consumer electronics

- Havells: Electrical products

- Crompton: Consumer electricals

- Voltas: Air conditioning

How to Apply

- Company career portals

- Naukri.com with “quality inspector,” “QC engineer,” “quality control” keywords

- LinkedIn job postings

- Manufacturing job fairs

- Placement agencies

Quality Inspector Salary in India

Salaries vary based on experience, industry, location, and company size.

Salary by Experience Level

| Experience | Annual Salary (INR) |

|---|---|

| Fresher (0-2 years) | ₹2.5 - ₹5 LPA |

| Mid Level (2-5 years) | ₹5 - ₹10 LPA |

| Senior (5-8 years) | ₹10 - ₹16 LPA |

| Lead/Manager (8-12 years) | ₹15 - ₹25 LPA |

| Head/GM (12+ years) | ₹25 - ₹40 LPA |

Note: MNCs and automotive OEMs pay 15-25% higher than tier-2 suppliers.

Salary by Industry

| Industry | Salary Range (Mid Level) |

|---|---|

| Automotive OEMs | ₹6 - ₹12 LPA |

| Pharma/Healthcare | ₹5 - ₹11 LPA |

| Auto Components (Tier 1) | ₹5 - ₹10 LPA |

| Heavy Engineering | ₹5 - ₹10 LPA |

| Electronics | ₹5 - ₹9 LPA |

| MSME Manufacturing | ₹3 - ₹7 LPA |

Salary by City

| City | Salary Range (Mid Level) |

|---|---|

| Pune | ₹5 - ₹11 LPA |

| Chennai | ₹5 - ₹10 LPA |

| Bangalore | ₹5 - ₹10 LPA |

| Delhi NCR | ₹5 - ₹10 LPA |

| Mumbai | ₹5 - ₹10 LPA |

| Ahmedabad | ₹4 - ₹9 LPA |

Salary Boosters

- ISO/IATF Auditor Certification: Premium for certified auditors

- NDT Certifications: Specialized testing skills

- Six Sigma Belt: Green/Black Belt valued

- Automotive Experience: OEM experience preferred

- CMM/Advanced Metrology: Premium for CMM operators

Certifications for Quality Inspectors in India

Professional certifications boost credibility and career prospects.

Quality Management Certifications

- ISO 9001:2015 Lead Auditor: Quality management systems

- IATF 16949 Internal Auditor: Automotive quality

- Six Sigma Green/Black Belt: Process improvement

- Certified Quality Engineer (CQE): ASQ certification

NDT Certifications (ISNT/ASNT)

- Ultrasonic Testing (UT): Level I, II, III

- Radiographic Testing (RT): Level I, II, III

- Magnetic Particle Testing (MT): Level I, II

- Liquid Penetrant Testing (PT): Level I, II

- Eddy Current Testing (ET): Level I, II

Industry-Specific Certifications

- GMP Training: Pharmaceutical quality

- AS9100 Internal Auditor: Aerospace quality

- Core Tools (AIAG): APQP, PPAP, FMEA, SPC, MSA

- GD&T Certification: Geometric dimensioning

ATS Tips for Your Quality Inspector Resume

Manufacturing companies use ATS to screen resumes. Optimise yours:

Keyword Optimisation

Include relevant terms like:

- Quality inspector, QC engineer, quality control

- ISO 9001, IATF 16949, quality management

- Inspection, testing, dimensional measurement

- SPC, PPAP, FMEA, root cause analysis

- CMM, NDT, metrology instruments

- Rejection rate, defect analysis

- Supplier quality, incoming inspection

Formatting Tips

- Use standard section headings

- List certifications with issuing bodies

- Include specific standards and tools

- Quantify achievements (rejection %, savings)

- Save as PDF for format preservation

Final Tips for Your Quality Inspector Resume

✅ Lead with certifications - ISO/IATF auditor credentials prominently displayed

✅ Quantify achievements - Rejection reduction %, cost savings, zero complaints

✅ Show industry expertise - Automotive, pharma, or specific sector experience

✅ Include measurement skills - CMM, conventional instruments, NDT

✅ Mention quality tools - SPC, 7 QC Tools, FMEA, root cause analysis

✅ Highlight audit experience - Internal/external audit participation

✅ Update regularly - Add new certifications and achievements

Quick Checklist

- Contact information complete

- Summary highlights quality expertise

- Skills include standards and tools

- Experience shows quantified achievements

- Certifications listed prominently

- Education with engineering details

- Clean, ATS-friendly format

Ready to create your professional quality inspector resume? Use our resume builder to get started with expert-designed templates.

Looking for more guidance? Check out our resume format guide for additional tips.

Frequently Asked Questions

What is the best resume format for Quality Inspectors in India?

Use a reverse chronological format with certifications prominently displayed. Include sections for summary, certifications, skills, experience, and education. Highlight ISO/IATF certifications, quality tools (SPC, FMEA), and quantified achievements like rejection reduction.

What skills should I highlight on a QC resume?

Highlight inspection skills (dimensional, visual, NDT), quality standards (ISO 9001, IATF 16949), quality tools (SPC, 7 QC Tools, FMEA), measurement instruments (CMM, conventional), and documentation skills. Include both technical and soft skills.

How much do Quality Inspectors earn in India?

Freshers earn ₹2.5-5 LPA. Mid-level (2-5 years) earns ₹5-10 LPA. Senior inspectors earn ₹10-16 LPA. Managers earn ₹15-25 LPA. Automotive OEMs and MNCs pay 15-25% higher. Certifications add premium.

Which certifications are valuable for QC careers in India?

ISO 9001:2015 Lead Auditor and IATF 16949 Internal Auditor are most valued. Six Sigma Green/Black Belt adds value. NDT certifications (UT, PT, MT) are essential for testing roles. Core Tools (AIAG) certification is valuable for automotive.

Is engineering degree required for QC jobs?

B.E./B.Tech in Mechanical, Production, or related field is preferred for engineer roles. Diploma holders can work as inspectors and progress with experience and certifications. Science graduates can enter pharma QC roles.

How do I transition from production to quality?

Get quality certifications (ISO Lead Auditor, Six Sigma), take on quality-related projects in current role, learn quality tools and standards, highlight process knowledge and problem-solving skills. Production experience is valued in QC.

Should I mention specific instruments on my resume?

Yes, include specific instruments like CMM (Zeiss, Hexagon), vernier calipers, micrometers, gauges, hardness testers, and NDT equipment. This demonstrates hands-on experience and helps with ATS keyword matching.

What's the career path for quality inspectors in India?

Typical path: Junior Inspector → Quality Inspector → Senior Inspector → Quality Engineer → Senior QE → Quality Manager → Quality Head. Alternatively, specialise in supplier quality, customer quality, or quality systems.

Does automotive experience matter for QC roles?

Yes, automotive industry experience is highly valued due to stringent quality requirements (IATF 16949). OEM experience is particularly valuable. Automotive QC professionals can command 15-20% salary premium.

How important is NDT certification for testing roles?

Very important for inspection and testing roles. NDT Level II certifications (UT, PT, MT, RT) from ISNT or ASNT are essential for NDT inspector positions. Higher levels command better salaries and supervisory roles.

Testing and Inspectors Text-Only Resume Templates and Samples

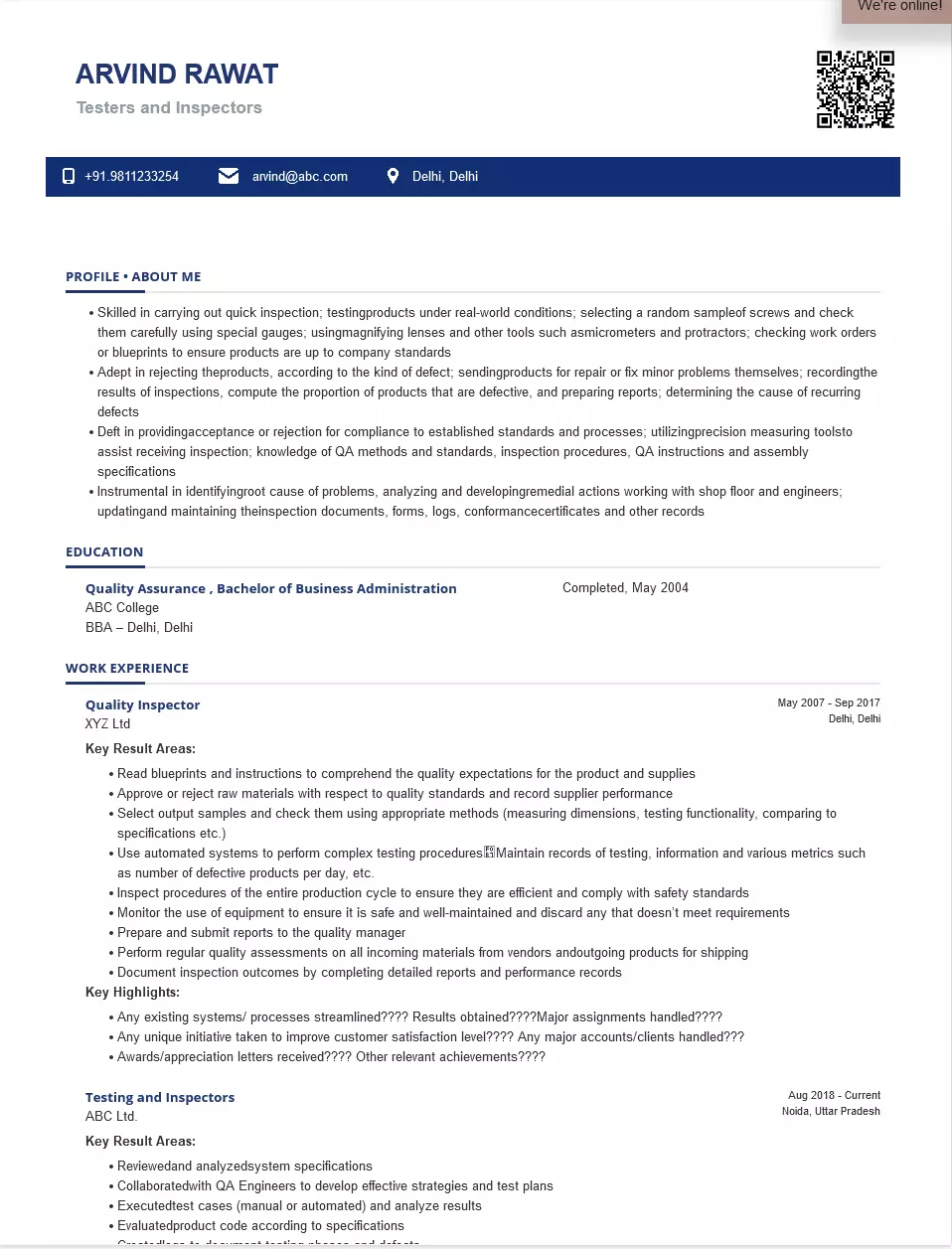

ARVIND RAWAT

Phone: 9811233254

Email: arvind@abc.com

Address: C-21, Sector-21, Delhi

About Me

Testers and Inspectors

- Extensive experience of XX years in checking raw materials, parts, and entire products that are being processed in a factory; making sure that each product measures up to the company's standards; keeping the quality of products high; complying with government quality-control regulations

- Skilled in carrying out quick inspection; testing products under real-world conditions; selecting a random sample of screws and checking them carefully using special gauges; using magnifying lenses and other tools such as micrometers and protractors; checking work orders or blueprints to ensure products are up to company standards

- Adept in rejecting the products, according to the kind of defect; sending products for repair or fixing minor problems themselves; recording the results of inspections, computing the proportion of products that are defective, and preparing reports; determining the cause of recurring defects

- Deft in providing acceptance or rejection for compliance to established standards and processes; utilizing precision measuring tools to assist in receiving inspection; knowledge of QA methods and standards, inspection procedures, QA instructions, and assembly specifications

- Instrumental in identifying the root cause of problems, analyzing and developing remedial actions working with shop floor and engineers; updating and maintaining the inspection documents, forms, logs, conformance certificates, and other records

Education

Quality Assurance , Bachelor Of Technology, Completed, May 2004

NIT Surathkal

– Marks null

Mangaluru, KA

Certifications

Work Experience

Period: May 2018 - Current

Quality Inspector / Inspection Engineer

Smiths Group

- Read blueprints and instructions to comprehend the quality expectations for the product and supplies

- Approve or reject raw materials with respect to quality standards and record supplier performance

- Select output samples and check them using appropriate methods (measuring dimensions, testing functionality, comparing to specifications, etc.)

- Use automated systems to perform complex testing proceduresMaintain records of testing, information, and various metrics such as the number of defective products per day, etc.

- Inspect procedures of the entire production cycle to ensure they are efficient and comply with safety standards

- Monitor the use of equipment to ensure it is safe and well-maintained and discard any that doesn’t meet requirements

- Prepare and submit reports to the quality manager

- Perform regular quality assessments on all incoming materials from vendors and outgoing products for shipping

- Document inspection outcomes by completing detailed reports and performance records

Period: August 2008 - April 2017

Testing and Inspectors / Inspection Engineer

ManpowerGroup Service Pvt Ltd

- Reviewed and analyzed system specifications

- Collaborate with QA Engineers to develop effective strategies and test plans

- Execute test cases (manual or automated) and analyze results

- Evaluated product code according to specifications

- Created logs to document testing phases and defects

- Reported bugs and errors to development teams

- Helped troubleshoot issues; conducted post-release/ post-implementation testing

- Worked with cross-functional teams to ensure quality throughout the software development lifecycle

Skills

- Computer

- Leadership

- Communication

- Organizational

- People

- Collaboration talent

- Problem-solving

- Marketing

- Design

- Analytical

Languages

Softwares

Operating System

Personal Interests

- Yoga

- Learning new Softwares

- Reading

India's

premier resume service

India's

premier resume service